These pages are a tribute to the aspirations and achievements of the many hundreds of men and women who have worked at Buckland Mill

By the end of the twentieth century the mill had become an example of efficiency improvement, achieved through modern manufacturing systems based on teamwork and flexibility.

Buckland Mill finally closed in June 2000, following a decision to improve shareholder value by concentrating manufacture at fewer mills. Production was transferred to the larger site at Stoneywood, Scotland.

For well over two centuries the people of the mill have risen to meet and exceed industrial and commercial challenges. In the late nineteenth century, the fulfilment of a stretching specification gave birth to Conqueror©, which has been maintained at the forefront of technical and aesthetic performance ever since.

This flexibility and co-operation was never more evident than during the year long closure and product transfer programme when quality, efficiency and service to customers were maintained at extemporary levels.

A culture of Continuous Improvement

Buckland Mill has long been renowned for the quality of its products and the Conqueror range of papers is highly regarded by fine paper users all over the world. This proud record of achievement is the result of willingness to change, flexibility, loyal service and effective management

In recent years, investment in technology at the mill has been enhanced by the adoption of world-class manufacturing principles: quality, safety and environment management, multiskilling and flexibility, teamwork and co-operation, and an appreciation of the importance of customer service.

Buckland Mill has led the way in meeting recognised national and international standards for quality and environmental management, safety procedures, and the training and development of its people.

In 1988 the mill was the first UK paper mill to achieve the BS 5750/ISO 9002 Quality standard. Accreditation for environmental standard ISO 14001, Investors in People, and many other awards were soon to follow.

1988 BS 5750 accreditation

1990 Dover wins the Arjo Wiggins Appleton Group Good Housekeeping Award. This was repeated in1991,1994 and 1996

1995 Gold Award for Occupational Safety from the Royal Society for the prevention of Accidents (ROSPA). This fine achievement was repeated for five years (1995 – 99)

1995 The Aylesford Newsprint Environmental Awards for Kent Businesses

1996 Investors in People accreditation

1997 Buckland Mill wins the Process category of the Management Today Best Factory Awards

Over the last ten years the drive to improve performance has focussed on planned and predictive maintenance, multiskilling and flexibility.

In 1999 the Total Productive manufacturing initiative was launched in the A4 line to further improve the mill’s efficiency. TPM involves one team of people – production and engineering – being totally responsible for the on-going care and maintenance of their equipment. By mid 1999 the A4 Line had achieved a significant efficiency improvement.

- 1990 Computerised maintenance management system and dual skilling initiative begins

- 1995 The mill adopts Thinking and Behaving Safely (TABS) to encourage employees to tackle safety issues themselves

- 1996 The mill is a founder member of a consortium of Kent paper mills who have agreed to train employees for the national recognised standards: NVQs (Nation Vocational Qualification)

- 1996 A segregated waste management system is introduced to enable Dover site to recycle most of its waste material

- 1999 Total Productive Manufacturing initiative was launched

Investment for Growth

When Buckland Mill reopened after the war in 1945, the challenge was to gear up to the Market

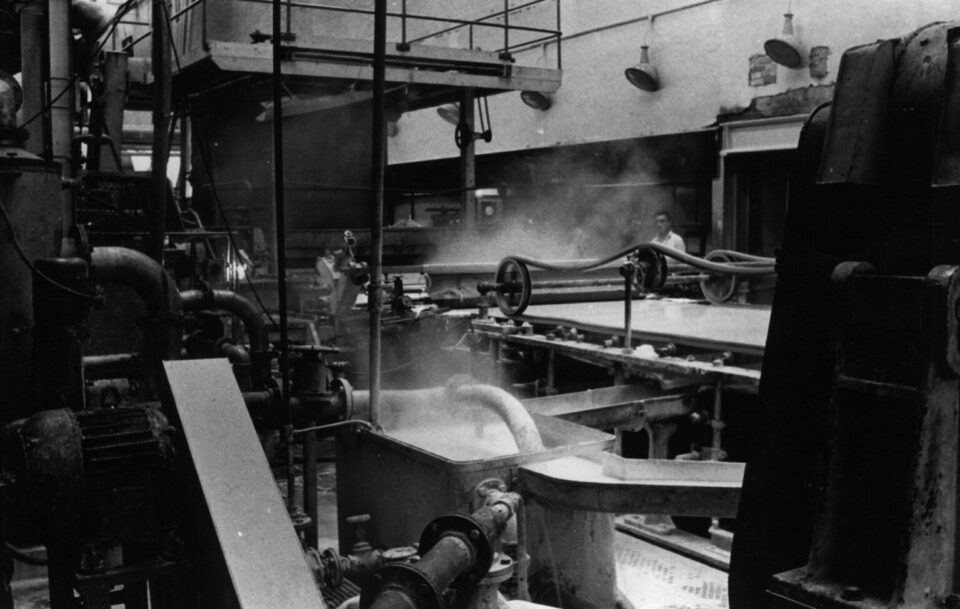

It was the beginning period that saw many challenges, in particular the use of cotton linter pulp to replace the hand sorting and boiling of rags.

Making specifications and colour matching suddenly became more exacting and the laboratory was extended to satisfy the more sophisticated aspects of modern paper making standards. Quality Control was introduced and a specialised colour matching laboratory was established.

Over more recent years investment has been directed towards increasing production capacity, improving product consistency and ensuring that the mill has a technical advantage.

In 1984 Precision Register Cutting (PRC) was developed followed by PRIC – a world first which enable Conqueror sheets to be precision cut with the watermark to register without guillotining. Sheet length and squareness improved, giving a quality advantage in the market, particularly the A4 segment. In the late 80s sorting and guillotining were automated, and hand wrapping changed to automatic folio packing.

The commissioning of the Combined Heat and Power plant in 1995 was a major step forward, changing ther old coal fired boiler to natural gas.

This was a collaborative venture between Scottish Hydro and Ajo Wiggins Fine Papers – the first between the public sector and a private company – and supplied Dover Harbour Board and Scottish Hydro with electricity as well as meeting the mill’s electrical and steam needs.

It has also had a dramatic effect on the mill’s environmental performance by reducing emissions to the atmosphere and use of road transport.

Annual Production

- 1895 800 tons – on two machines

- 1910 2300 tons – on three machines

- 1938 4285 tons – on three machines

- 1959 8086 tons – on three machines

- 1998 27500 tons – on two machines

1947 A new raghouse was built and crabble mill became a storage and export packing area

1950s Cutter register control “by eye” gives way to automatic control using war surplus electronics, reams were still finished by guillotining

1956 The old steam boiler house with its six hand fired Lancashire boilers was replaced by a Clarke Chapman grate feed water tube boiler and for the first time additional electricity was brought into the mill

1957 A new workshop was built to house the maintenance department

1958 The various offices scattered throughout the mill were brought together

1960 Instrumental colour matching began in the laboratory, using analogue COMIC computer for Plastic Base Paper

1970 A new Conqueror warehouse and office block were built

1984 Precision Register Cutting was developed

1989 No 1 machine was closed and sold to Tunisia; the plastic base business was transferred to James Bibby at Devon Valley

1991 A broke handling system for both machines was installed

1995 The Combined Heat and Power Plant was commissioned

1999 PM3 Valmet process control, including fully profiling grammage moisture, ash, thickness and automatic colour grade change

The Building of a World Class Brand

Conqueror, the best known watermarked paper in the world, was first produced at Buckland Mill in 1888 and remained the mill’s premier brand for 122 years

Today, Conqueror is the world’s leading business stationery and has been developed to include papers such as Conqueror CX22 designed for use on modern office equipment, and IConquerorI for dDigital specifically for the fast growing digital print market

Eventually the oprder was taken by Henry Hobday who was struggling to rebuild the business at Buckland Mill after a disasterous fire in 1887. It covered all Ledger sizes from Cap to Imperial and was made during the later part of 1888. Mr Barlow was very pleased with the result and put Conqueror London on the market for four pence halfpenny per lb (4½d).

In the late 1880s Mr E P Barlow, a director of the London based stationers Wiggins Teape, became intent on marketing watermarked paper of his own. It was to be a very high specification quality paper called Conqueror London. He had also decided what price he would pay and even written out an order for a first making. However the price was so low that no mill owner would take it. Priced at three pence and three farthings per lb (3 ½d), it was to be principally rag, tub-sized and air dried.

In 1890 Buckland Mill was bought by Wiggins Teape for £20,000 and saw rapid expansion in capacity. The mill price for Conqueror was increased to Four pence per lb and Henry Hobday run the mill for the new owners.

The period between the two World Wars was one of consolidation and improvements. No 2 machine was rebuilt: two humidifiers were installed to condition the paper and a modern reeler replaced the old drum reelers.

- 1906 Lewis Hobday Succeded his father in operating Buckland Mill

- 1910 No 3 Machine – the Conqueror Machine – went into operation

- 1927 A new wet-end was installed on No 2 machine

- 1936 A steam turbo generator replaced the outdated steam engines and the mill was completely electrified

- 1937 The dry-end of No 2 machine was remodelled

- 1940 An RAF Spitfire crashed into the roof

In 1895 Crabble Mill was bought by Wiggins Teape and converted into a rag preparation and boiling department for Buckland Mill. By the turn of the century, over 200 people mostly female were engaged on this work. In 1905 it burned down in spite of valiant efforts of the rag sorters. It was rebuilt along with a Social Club in recognition of the rag sorts’ attempts to save it and remained in operation for another 40 years.

A Long Tradition of Paper Making

Paper was being made at Buckland Mill probably as early as 1638. The Mill was to have a very important part in the early history of machine-made paper, through the transition from hand-made paper produced with little technical knowledge to the age of machines, technology and science.

In its early years, Buckland Mill, one of six on the River Dour, was run as a cottage industry employing two or three people including an apprentice. Paper was made by hand, and the mill would have produced a few hundredweight per week.

1746 Thomas Horne, who had leased the mill from the Archbishop of Canterbury and was helped by his apprentice Daniel Hobday, died. The mill was inherited by his sons Ingram and Thomas Horne

1814 Following a fire, the mill was rebuilt and considerably enlarged. Paper was still produced by hand and the rags were boiled in open tanks

1817 The mill was for sale as ‘A Capital freehold paper mill having a large breast shot water wheel ssupplied by a powerful stream, capable of working six vats with presses, drying lofts, it has a space for another waterwheel and a reserved convenience for putting up a machine’.

1822 George Dickenson, younger brother of John Dickenson of Croxley, leased the mill at a time when a revolution was taking place in paper making. A machine to make paper, developed in1805 was much talked about.

1823 A Fourdrinier paper making machine for making a continuous sheet paper of indefinite length was installed, and for Buckland Mill, this marked the end of hand–made paper and papermaking as a cottage industry

1823 Buckland House was built by Thomas Horne

The Development of the paper making machine, along with improved conditions of life generally, the advance in education and the increase in population, all had an important effect on papermaking during the 19th century

1838 Buckland Mill was advertised to let as ‘most eligible and desirable’ and ‘famed for the quality of its paper’. By now it was producing white papers as well as traditional blue and brown

1849 Charles Ashdown bought the mill which was run by his son Henry. When Henry died in 1877, his brother Charles came into the business from banking but with very little knowledge of paper-making. Henry Hobday, General manager at Snodland Mill, was offered an equal partnership in the business traded as Ashdown & Hobday. The partnership was a success and the business prospered

Weekly production rose from two to seven tons across a wide range of papers – from browns to banks and ledgers. The mill was well known for high grade writings and ledgers. There was a good business in bag making, general printing and account books.

The mill had one machine making paper at 48 inches wide. This was increased in later years to 51 inches wide to accommodate 3 sheets Large Post. Weekly production slowly increased to eight to nine tons and annual profits rose to about £4,000. Henry Hobday always looked after the London business going there nearly every week looking for orders among his many friends in the trade.

1887 When business was booming, the mill was totally destroyed by fire. No 1 machine was rebuilt and remodelled, and output was increased from three to twelve tons per week. The first spherical rotating rag boiler was installed. But much business had been lost and finances were low.

1888 In a desperate attempt to rebuild the business, Henry Hobday took the order for the first making of Conqueror London

Crabble Mill, also on the Dour, was built around 1790 by the Phipps family, John Phipps patented a method for producing watermarked lnes in paper as a method of teaching writing and drawing, and in 1825 John and Christopher Phipps patented the Dandy Roll.

In 1807 just two years after the first paper machine was perfected, the Phipps installed one at Crabble.